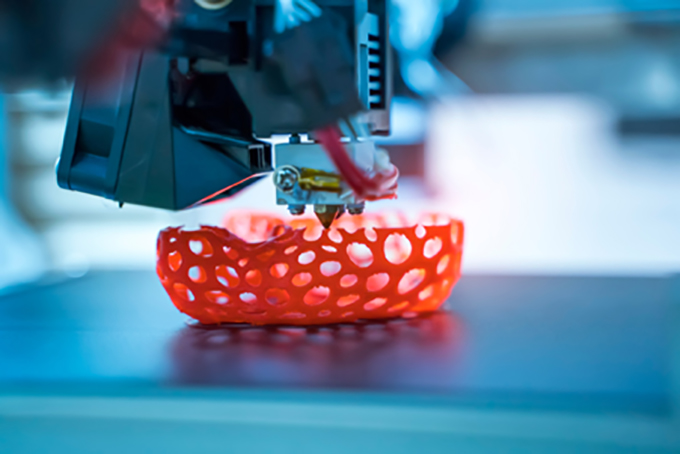

The manufacturing industry has evolved with the development of additive manufacturing technologies. Today, companies use various designing, development, manufacturing, and distribution processes beyond 3D modeling.

However, many companies are still unaware of the advantages rapid prototyping processes can provide to their industry. Here are some ways in which the rapid prototyping process can transform the automotive industry.

Product Innovation

Custom CNC machining is a valuable technology that allows automobile manufacturers to create parts that don’t exist anywhere. A custom part can be anything like a new gear mechanism. Traditional manufacturing processes often have limitations in the creation of new designs. The rapid prototyping processes allow the automotive industry to make plastic prototypes with fewer design constraints.

The flexibility offered by additive manufacturing processes allows automobile manufacturers to create parts with customized characteristics. Hence, manufacturers can add improved functionalities like less weight through lattice structures, integrate electrical wiring inside the part through hollow structures.

The rapid prototyping process allows automotive companies to create complex geometries that are not possible with traditional manufacturing processes.

Iterative R&D

Iterative design allows product developers to create and test designs quickly. The designs that show promise can be iterated rapidly using an additive manufacturing process. Designs that fail to work as intended can be abandoned. Rapid prototyping is a cost-effective approach that allows designers to put user experience at the heart of the design and development process.

Custom CNC is specifically used to deliver innovative automotive parts to the world that is impossible with traditional manufacturing. Rapid prototyping improves prototype workflows and reduces development times.

Several automotive manufacturers in the US use additive manufacturing technologies in initial prototype assembly. According to experts, additive manufacturing is so popular that US auto manufacturers complete 80 to 90% of initial prototype assembly using rapid prototyping technology.

The additive manufacturing technology is used to make part of ducting and exhaust and air intakes. The automotive parts are designed digitally printed using custom manufacturing processes and fitted on vehicles in short order. The product developers test multiple iterations to analyze the performance of the design before finalizing the design specifications.

Rapid prototyping helps achieve a shorter development phase and allows automotive companies to reduce time to the final part.

Prevent Supply Chain Disruption

Most automotive companies follow a just-in-time manufacturing strategy where large quantities of automotive spare parts are delivered to the assembly line before scheduled production. This strategy has proved helpful in reducing warehousing costs. Rapid prototyping can create production parts on-site if there is any disruption to the supply chain.

For example, consider a scenario where the company has planned a new car release in the 1st week of January. However, the tooling of the box that contains the engine control unit was not manufactured correctly. The result would be the launch of the new car has to be postponed.

You can avoid such situations by rapid prototyping process. For example, you can use rapid prototyping processes to produce engine control units in-house for the first batch of hundred cars. The CAD file can be optimized for 3D printing, allowing the automotive manufacturer to get end-use production parts quickly.

Specialty Car Industry

Several specialty car manufacturers design and develop luxury cars, sports cars, and hypercars for the elite. These cars are customized to meet the needs of the client. Traditional manufacturing processes cannot be used in the specialty car industry as the order involves developing only a few cars and not mass production.

Rapid prototyping processes allow car manufacturers to produce exotic cars in small numbers for their discerning customers. Since these are customized cars, the car manufacturer has to develop parts out of the ordinary. The additive manufacturing technology can create custom spacers, brackets, grommets, and specialized units as per client requirements.

Electric Vehicles

The automotive industry is slowly shifting to environmentally friendly technologies. Today, every car manufacturer has expressed a desire to launch an electric vehicle. The incorporation of batteries as a power source has not changed the design fundamentals in the automotive industry.

Even today, car designers and engineers strive to reduce the weight of the car to improve mileage. The additive manufacturing technology allows designers to explore different ways of creating components to achieve a weight reduction.

The rapid prototyping technology allows engineers to test unique geometries and produce a single final part for assembly with reduced weight. The result is a reduced burden on the electrical motors that drive the vehicle, increasing the range.

To sum up, rapid prototyping processes allow the automobile industry to put new ideas into production while cutting the development costs and reducing product development time. It provides several advantages to the automotive industry that includes the development of defect-free and high-quality products. Get to know more about the rapid prototyping process, please go here